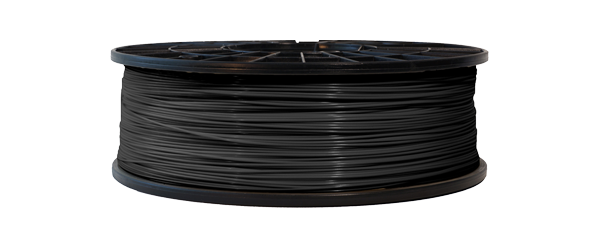

ABS - FDM Thermoplastic

ABS material properties

ABS (Acrylonitrile Butadiene Styrene) is a popular thermoplastic material used in 3D printing. This versatile material is known for its strength, durability, and temperature resistance, making it an ideal choice for a wide range of applications.

One of the primary advantages of ABS is its ability to produce parts that are both strong and durable. This makes it an ideal material for creating functional prototypes and end-use parts that need to withstand demanding environments. ABS is also easy to post-process, allowing users to perform various finishing operations such as sanding and painting. This enables users to create highly detailed and aesthetically pleasing parts that are suitable for a wide range of purposes. Another benefit of ABS is its thermal stability. The material can withstand temperatures of up to 80°C without losing its structural integrity.

Overall, ABS is a versatile and reliable material that offers a wide range of benefits for users. Whether you're a product designer, engineer, or manufacturer, ABS is a great material to consider for your 3D printing needs.

Good to know

You can save up to 50% with our FDM materials compared to the OEM!

Different colors available.

ABS Applications

Prototyping

Tool Manufacturing

Mass Production

Contact us to find the best material for your application

Did you know?

ABS material should be stored in its airtight packaging at room temperature until processing, as the plastic tends to absorb moisture. To avoid problems while printing, the material should not become humid.